Not Impossible Labs: Project Daniel

Joseph Maduma

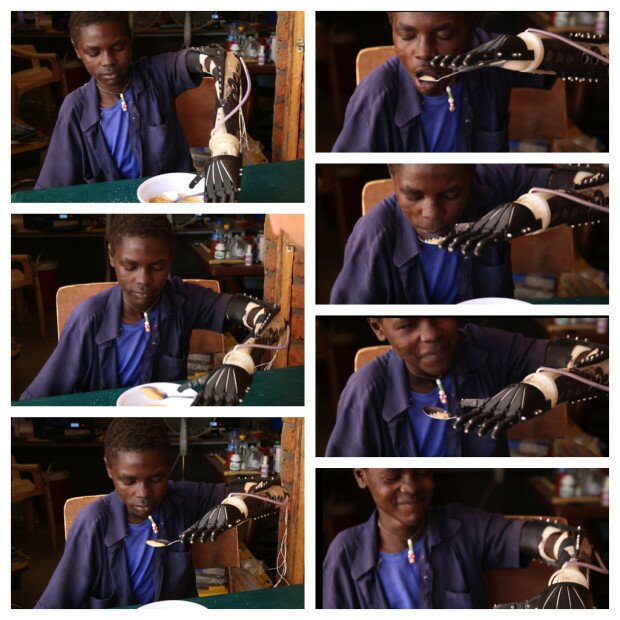

March 19th 2014A California media and technology company is using 3D printing to provide hands and arms for amputees in South Sudan and the war-torn Nuba Mountains. In November 2013, Not Impossible printed a prosthetic hand that allowed a teenager to feed himself for the first time in two years.

Project Daniel is the second life-changing project that Not Impossible has unveiled. In 2010, company CEO & founder Mick Ebeling spearheaded the creation of the Eyewriter, eye-tracking glasses with free, open-source software that enabled a renowned graffiti artist paralyzed by ALS to draw and communicate using only his eyes. The technology was lauded in Time magazine’s “Top 50 Inventions of 2010,” was named to Gizmodo’s Eight Incredible Health Innovations that Transform Lives, and became the subject of the award-winning documentary “Getting Up.”

“We’re hopeful that other children and adults in other regions of Africa, as well as other continents around the globe, will utilize the power of this new technology for similar beginnings,”

At the end of 2013, Mick Ebeling returned home from Sudan’s Nuba Mountains where he had set up the world’s first 3D-printing prosthetic lab and training facility. On his journey Mick managed to give hope and independence back to a teenager named Danial who, at age 14, had both his arms blown off and considered his life not worth living.

Just prior to the trip, the now 16-year-old Daniel was located in a 70,000 person refugee camp in Yida, and, on 11/11/13, he received version 1 of his left arm. The Daniel Hand enabled him to feed himself for the first time in two years. He even managed to eat chocolate for the first time.

After Daniel had his own “hand,” with the help of Dr. Tom Catena, an American doctor working under extreme conditions, the team set about teaching others to print and assemble 3D prostheses. By the time the team returned to their homes in the U.S., the local trainees had successfully printed and fitted another two arms, proving the project will have lasting benefit beyond the team’s presence.

One of the huge milestones achieved through Project Daniel was that it successfully unfolded in a region where a cease-fire had expired (and where fighting has now escalated), and that the people taught to utilize the 3D printers were barely familiar with computers, let alone the idea of 3D printing. This along with the fact they cost only £60.00 to produce demonstrates that there is clearly the potential for global impact.

“We’re hopeful that other children and adults in other regions of Africa, as well as other continents around the globe, will utilize the power of this new technology for similar beginnings,” said Not Impossible founder Mick Ebeling. “We believe Daniel’s story will ignite a global campaign. The sharing of the prostheses’ specifications, which Not Impossible will provide free and open-source, will enable any person in need, anywhere on the planet, to use technology for its best purpose: restoring humanity.”

“Use technology for its best purpose: restoring humanity.”

The Daniel Hand came to fruition at Not Impossible HQ in Venice, California by crowdsourcing a dream team of innovators (including the South African inventor of the Robohand, an Australian MIT neuroscientist and a 3D printing company owner from Northern California) to crowd-solve the 3Dprintable prostheses. The project was supported by NY-based precision engineering company Precipart and by Intel, a global leader in innovative essential technologies.

“We are on the precipice of a can-do maker community that is reaching critical mass,” said Elliot V. Kotek, Not Impossible’s content chief and co-founder. “There is no shortage of knowledge, and we are linking the brightest technical minds and creative problem-solvers around the globe. Project Daniel is just the tip of the proverbial iceberg,”